Overview

Since 1978 we have trained thousands of students, and our courses speak for themselves! Our instructors come highly recommended and make training an enjoyable experience. At FTT, our clients see an immediate return on their training investment by reducing building, equipment, racking and product damage.

Make sure your management team and operators are competent and in full compliance with the OHSA.

Please note that FTT offers its services to municipalities and industrial companies, and does not offer public training sessions.

Don’t be misled and fail to train on small equipment or identify the hazards associated with: Trimmers, Blowers, Chain Saws, Cultivators etc.

New Operator Evaluation

Have you ever hired an inexperienced operator? When hiring new or experienced operators do you conduct a practical evaluation prior to hiring?

If so, when you do, make sure these new operators have gone through FTT’s proven method of evaluating new hires and received the proper training. It’s the Law!

Let's make sure that if your employees use equipment, your company does not become a statistic.

Refresher Evaluations

Good training takes time! If you take the time, you will see the results.

Anyone can drive a equipment, however not everyone is an "operator"! Take a look around your plant. You can soon separate the “drivers” from the “operators” by the amount of damage you have in product, equipment, building and racking; not to mention near misses.

Allow FTT to quote on your training requirements and you will see an immediate return on your training investment.

Grounds Maintenance

Established in 1978, FTT has set the standard for training on grounds maintenance equipment.

We do not sell or service any type of equipment. Our specialty is training members of your staff whether it be operators, supervisors or managers. FTT offers a complete package where our experienced instructors ensure that a visit from the MOL will find no stone unturned. We train on all equipment from trimmers to tractor mowers, loaders etc. While our instructor is on your site, you will be informed of any deficiencies.

Don’t be misled and fail to train on small equipment or identify the hazards associated with: Trimmers, Blowers, Chain Saws, Cultivators etc.

Request a Quote

Statistics in Canadian industry

Between 1990 and 2006 a total of 1161 patients visited Canadian hospitals for mower related injuries. These figures are for small equipment only, not counting chain saws - (32%) lacerations, (16%) amputations, (23%) slipping under mowers.

With a great deal of this type of equipment being used at homes across Canada, one wonders what are the accident stats for homeowners? Over the years of training grounds personnel, we find that many had never used small equipment before. So when they get a part time job with a golf course or municipality, it may be their first time operating a piece of equipment.

Let's make sure that if your employees use equipment, your company does not become a statistic.

Forklift

Forklift Training (OHSA Reg 851 – CSA B335-15)

Forklift trucks come in all shapes and sizes and are classified under their rated capacities, ranging from the pallet truck capacity of 4000lb through forklifts with 200,000lb capacity.

These machines are found in all types of industry and used for handling pallets, concrete pipes, steel rolls, lumber and many other products.

Because of the flexibility of forklifts, each machine comes under a specific class and lift code. There are 7 classes and 21 lift codes.

In order to be in compliance with OHSA and CSA standard on forklifts, operators have to be deemed competent on each class and code they operate. They must also receive training in their own working environment and with their own machine/product. Don’t be misled! Ensure your documentation/certification and wallet card indicate the class and code.

Request a Quote

Forklift Training Updates

Ontario Ministry of Labour Update on Storage and Material Handling Safety - During February and March, 2014 inspectors will be looking for hazards in warehouses and storage areas.

Proper use of forklifts is a key aspect of these reviews. Read the full MOL bulletin below.

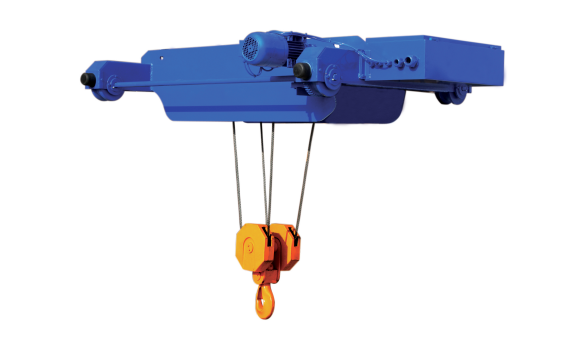

Overhead Crane Operator

Crane Operator Training - Crane Operation and Rigging CSA B167-08

If you work around cranes, slings and rigging, it is critical to be thoroughly familiar with the safe operation of all of the tools and equipment involved.

A competent rigger will tell you every lift can be divided into three parts: Lifting Device - Hitch - Load.

Make sure that your operators understand what type of sling is to be used, along with the type of hitch and applied load angles . . . because once the rigging is off the ground, it is too late! FTT has provided specialized courses in crane operator and rigging safety since 1978.

Request a Quote

Overhead Crane Operator Training - Update

Ontario MOL Alert: Beam Clamps (Lever-Action)

From the Ontario Ministry of Labour -- (link to full article below)

Two workers on a construction project were struck and killed when a structural steel beam being hoisted over them slipped out of a lever-action beam clamp.

The investigation revealed that the single clamp being used was too large for the beam and so did not grip the top flange securely. It was also discovered that the clamp used a lever action for gripping. When the tension on the hoist cable was released, the jaws of the clamp could open automatically and release its grip on the flange.

Mobile Crane Operator

Mobile Crane/Rigging 0-8 ton MTCU Construction Program P: 930030

OHSA regulation 213 Section 150 [1] stipulates that no worker SHALL operate a crane or similar lifting device capable of lifting greater than 7260kg unless the worker is certified as a “hoisting engineer” under the Trades Qualification and Apprentice Act O.631/194,s.3. Capacities below this require operator proof of competence.

Although MTCU participation is voluntary, FTT has developed a program that is in line with the MTCU requirements and meets OHSA/MOL requirements.

All aspects of crane operation will be covered from crane signals – Wire and synthetic rope – Rigging and rigging hardware – Load charts – Crane Capacity and configuration – Boom extensions – Inspections etc.

This course is certified with current documentation.

Request a Quote

Mobile Crane Operator Training - Update

From the Ontario Ministry of Labour, Jan. 14, 2014 -- (link to full article below)

An articulating boom crane truck (“crane truck”), similar to that in Fig.1, was brought into a mechanical garage to undergo repair of a hydraulic leak in an extension cylinder. The articulating boom, also known as a knuckle boom, was mounted at the back of a flatbed of a crane truck and had a lifting capacity of 6000 kg. The articulating boom consisted of an inner boom and an outer boom with a boom extension, which could extend out of, and retract into, the outer boom.

In order to verify that the leak had been repaired, a worker at the garage extended the boom extension out of the outer boom while the articulating boom was in the stowed / travel position. This action caused the inner boom to come out of its rest position and move upward causing the outer boom and extension to suddenly drop approximately eight feet, due to a cantilever effect from the weight shift.

Read the full resource update by the MOL

Shunt Trucks

Presented by Humber College (Theory & Practical)

On numerous occasions, we find that companies are not aware that shunt truck operators require training to be in compliance with OHSA. This program is conducted by Humber College on your premises with your own equipment. Humber certification is well respected throughout industry.

Request a Quote

Aerial Work Platform

Aerial Work Platform Training CAN 354 1-2-3-4 M82

Scissor Lifts – Knuckle Boom – Straight Boom

If you have a lift platform, then you have come to the right place for training. There are numerous accidents associated with aerial work platforms.

These lifts are such an integral part of industry and many times are overlooked when it comes to ensuring the operator is competent. Make sure that your employees have the necessary training and have also received Fall Protection training as well.

Request a Quote

Floor Sweepers

Cleaning Equipment Sweepers/Scrubbers/Swing machines

Are your operators trained on this equipment? Powered equipment comes in many shapes and produces a variety of results.

Your ride on or walk behind a powered sweeper presents significant hazards not only to the operator, but to other employees as well. Wet floors and poorly positioned signage present slip and fall hazards to pedestrian travel.

Reduce building/equipment damage and limit liability by ensuring your operators understand the safe operating procedures when cleaning your facility.

Request a Quote

Power Pallet Trucks

Power Pallet Trucks Class 3 lift Code 1-8

Are your operators trained on this machine?

This machine will handle as much weight, if not more, than your conventional sit down rider lift truck. Although there are more accidents associated with operating this machine, owing to the vulnerability present to the operator, we find that many operators have not received training.

FTT will ensure that your operators are brought up to the standard!

Request a Quote

Non-Powered Pallet Trucks

Non-Powered Pallet Trucks OHSA Reg 851

Did you know that your operators require training on this Non-powered Pallet Truck?

Every year numerous accidents are reported; Feet crushed - Hands crushed - Running into racking, walls etc. Do you, or more importantly your operators, know how to stop this device in an emergency?

Call FTT and we can help answer your questions.

Request a Quote

Working at Heights

Working at Heights/Fall Protection Z259 1-15

Fall protection, travel restraint, fall arrest, what are your training requirements? Fall Protection does not only apply to wearing the correct harness and lanyard. Fall Protection applies when a worker is exposed to the hazard of falling and the surface to which he/she might fall is more than three metres below the position where he/she is situated.

FTT and its partners can engineer, design and install a system in your facility. We will also train your personnel in the correct fall protection, ladder safety and harness inspections as required under the OHSA.

Request a Quote

Working at Heights Training - Update

This video from Workplace Safety North discusses the importance of erasing hazardous falls in the workplace.

Have a look at this interesting video: "Erase the Hazard - Falls"

Utility Vehicles

Utility Vehicles OHSA Reg 851

Personnel and Burden Carriers, etc. are as prone to accidents like any other mobile equipment.

Once trained, these machines are not difficult to operate. However the hazards and basics must be understood. Topics such as fuel handling/battery maintenance, working environment and load capacity must be understood by the operator.

FTT specializes in training for all types of material handling and transport equipment.

Request a Quote

WHMIS

WHMIS OHSA Reg 860

WHMIS can be a dull program and therefore be taken lightly. However, the incorrect handling of materials and improper or lack of documentation can have a very serious impact.

Controlled goods do not only require due diligence in the workplace, but also in your own home; especially where children are present.

Let FTT bring this program to life for you with our highly qualified instructors.

Request a Quote

Skid Steer & Wheel Loader

Wheel/Track loaders and Backhoe/Excavators OHSA Reg 851-213-854

Skid-steer, articulating, straight frame, backhoes and excavators require operator due diligence at all times.

Whether the operator is new or experienced, ongoing training is required. As with all types of powered equipment, accidents can have serious repercussions.

Because of the numerous types of equipment and the variations of controls, it is essential that operators are trained on the job with their own piece of equipment and in their own working environment. Different soil densities and gradients need to be taken into consideration at all times.

Request a Quote

Management Seminar / Workshop

Material Handling Management Seminar / Workshop

The objective of this course is to provide supervisory and management personnel with the knowledge and safety principles required for understanding their responsibilities when working with material handling equipment and their product, in order that they may take a proactive approach to accident prevention within the company’s program for safe operation of equipment.

Topics covered:

- Duties of a Supervisor

- Legislation and Standards

- CSA Z1000-6

- Workplace & Equipment Inspections

- Cranes

- Aerial Work Platforms

- Lift Trucks

- Grounds Maintenance Equipment

- Fall Protection

- Power Sources

- Standard Operating Guidelines

- Investigations & Report Writing